A Comprehensive Guide to Sheath Tubing

24 February 21

A Guide to Sheath Tubing

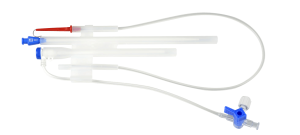

Sheath tubing has a complex design. Sheath tubing has a firm elongated tube at one end so that an elastic sheath joins it. The other end of the elongated tube connects with a surgical hand-held machine tool.

Two elastic tubes make use of different purposes. One elastic tube is for creating a barrier against tainting of an aspirating tube, and another for obstruction of irrigation tubing. With the help of these elastic sheaths, the elongated tube secures the surgical procedure. Each kind of sheath tubing is foldable and expandable. The sheath tubing also connects to a capsule of selected components of a surgical pack.

The background behind the Invention of a Sheath Tubing

The ocular surgery procedures with surgical hand-held machine tools needed an invention that provides elastic tubing. This elastic tubing also known as sheath tubing helps in forming a sterile barrier for aspiration tubes as well as sterilized apparatus. Discussion of the related art

Medical science includes various kinds of surgical procedures that demand hollow sheath tubing to transport fluids, tissues, blood, etc. This can be one or more than one to perform a given surgery. Also, they are sterile and packed in a tray. The transferring and removing of fluids deposit using a channel of sterile, hollow tubing covered in a casing.

Sheath sterile tubing usage fulfills desired surgical procedure and demands a certain amount of time to install. They may be expensive or cheap according to the type of material used in any particular surgical kit. It may vary from supplier to supplier as well as to the material used.

During a surgical procedure, hygiene is of utmost importance. The handling must take place with care during usage of the sheath tubing in surgery. In addition, the external surface needs proper care from getting contaminated by the environment.

In some cases, the tube can be re-used. It requires proper removing and sterilizing before re-use. This process of re-using needs highly professional staff and time. It can be costly as well.

In many cases, this method can be dangerous as it needs much efficiency. Even a little amount of negligence can lead to a big loss. Performing all the aspects of cleaning with efficiency can help recycle the sheath tubing. Cleaned tubing can cause threats and life risks.

Uses of a Sheath Tubing

Sheath tubing has its uses in different fields of medical sciences in various ways. Each field gets its benefits in different ways. Major Fields that involve the use of sheath tubing in their procedures are Infusion technology, Endoscopy, and Gastroenterology, Urology, Cardiovascular EP, Gynecology, and Analytics, etc.

Features of a Sheath Tubing

Materials in which this kind of tubing is available must be FEP (Fluorinated ethylene propylene) and ETFE (Ethylene tetrafluoroethylene). These are high-quality translucent polymer plastics that help perform tasks skillfully.

Different fields require a different size, color, and hardness of the tube. Their design takes a lot of input with proper assistance from professionals. It must have magnificent radiolucent visibility that allows x-ray beams to pass through them.

The sleek surface is a very important feature that allows it to enter the body easily. The easy curving ability and elasticity can influence greatly while doing a surgical task.

Deep Medical Tubing Expertise

The tubing line of DTC has become larger to cover specialized items such as polyimide tubing, PTFE tubing, and a full scale of single and multi-layer squeeze-out tubing.

The ultrathin, high-strength, and extremely accurate heat-stabilized non-shrink tubing, ideal for precision sheaths or covers, catheter tubing and liners, insulating sleeves, and observe windows, remain structurally resistant at high temperatures as 100 C(212 F) or inflated.

Abstract View of a Sheath Tubing

An acrobatic sheath is stable till the end of an unbending extension tube. The additional end of the unbending extension tube stays connected with a surgical handpiece. Two supple sheaths can help as a blockade as opposed to the pollution of inclination tubing and the other as a shield against pollution of artificial process tubing.

This occurs by attaching two supple extension tubes between the surgical handpiece and a related one of the aspiration and irrigation tubing. Each flexible sheath falls into pieces and expands so they may be expanded during a collapsed atmosphere over the associated aspiration or irrigation tubing.

This way they can link in the expanded condition. The expectation or irrigation tubing connects to a cassette of a surgical pack which helps in the surgery.

Discussion Regarding Sheath Tubing

The current innovation relates to a sterile tubing sheath as a part of a sterilized barrier apparatus. To perform a procedure of forming a sterilized barrier for an aspiration tube used with a surgical handpiece in ocular surgery procedures.

During different types of surgical procedures, one or more sterile, hollow tubing usage aids in carrying fluid to the eye and to carry fluid, tissues, blood, etc. Such surgical procedures demonstrate certain ocular procedures such as cataract elimination and vasectomy operations.

Such sterile, hollow tubing generally sells in a mixture with a “cassette”, which is a cluster vehicle into which the extracted out fluid, tissue, etc. houses. In addition, the combination of one or more infertile, hollow tubing and the armor refers to a surgical pack.

Usually, this happens as soon as desired or irrigation tubing uncovers for a patient. Such kind of tubing is known to be polluted because that the process cannot be reprocessed during a succeeding operation correct sterilization following the motive.

However, only the sheaths and the tiny addition tubes would pollute upon subjection to the patient or ungloved hands of technicians or surgeons. Also, the sheaths and the tiny extension tubes must discard after each surgical process.

The aspiration and irrigation tubing wrap by the sheaths and the cassette to which the tubing attaches. They can become useful again after executing the previously mentioned sterilization technique.

This also allows the resistless tendency for the irrigation tubing. While the preceding description and drawings constitute embodiments of the present creation, the various swapping and tempering can depart without deviating from the scope of the present creation.

Composing of the sheath tubing

Dutch Technology Catheters have a wide and flexible medical tubing line. There is a large selection of polyimide tubing features that have a very thin wall thickness, tight tolerance in inner and outer diameters. For this purpose, excellent electrical insulation possessions, stiffness, and column strength are core requirements.

There are certain methods of tubing such as PTFE tubing. It is refined using a sintering method where the substance heats up to a temperature below its melting point for an extended period. In the present time, split sheath introducers and violators are in high demand. In inclusion to this, it also uses lubricious catheter liners and heat shrink tubing.

Conclusion

Due to the chemical firmness and low co-efficient of friction, PTFE is an ideal catheter liner. Now if we come to the properties of PTFE it has the lowest coefficient of friction of any polymer making it an approved choice for catheter application that requires lubricity. It also attributes to the temperature and chemical defense in biocompatibility.

Also, Sheathing tubes have explicit tolerance with high dielectric strength with sterling neutralizing properties. DTC has a satisfying track history of supplying high precision and specialized express tubing to medical devices to industries and many more. Hence, it is becoming the most widely used medical apparatus.

For More Products, Visit Our Website Today!