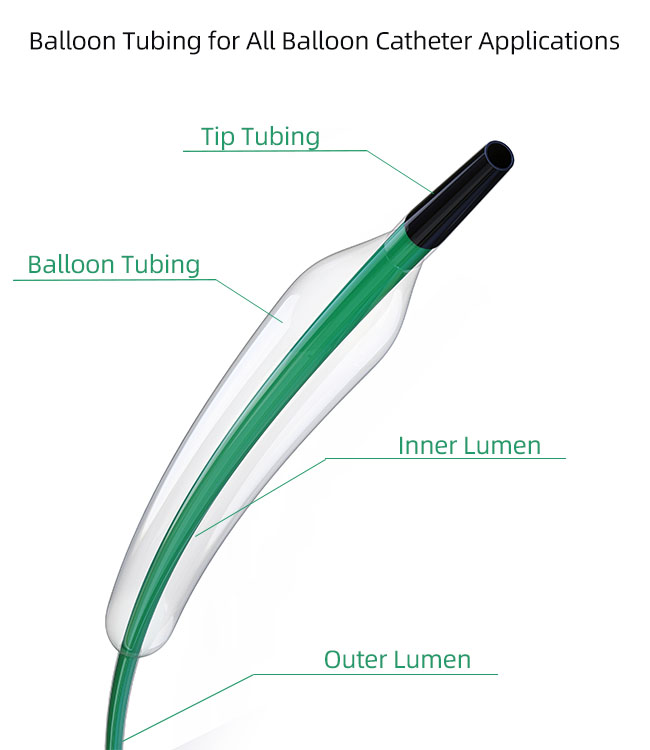

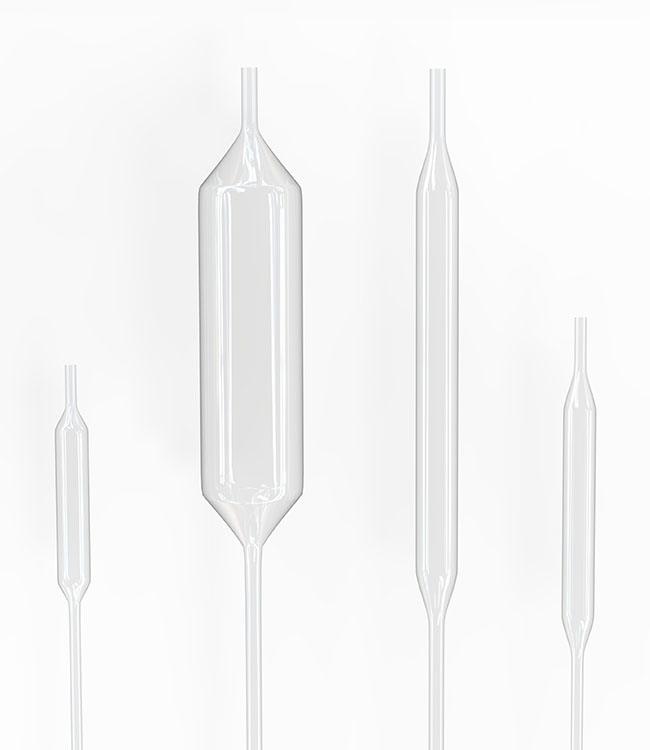

Balloon Tubing

At AP Technologies, we recognize the role concentricity, dimensional stability, and tightly controlled tensile parameters play, in order to maximize yield rates during the balloon forming process for our customers. All our balloon tubing is manufactured out of clean room facilities utilizing state-of-the-art balloon extrusion equipment. Our experienced manufacturing engineers, quality team, and operators work together to ensure that the highest quality balloon tubing is delivered to our customers.

Features

- Biocompatible, USP Class VI compliant

- Ultra-thin wall balloon tubing

- Dual and Tri-layer balloon tubing

- High and reliable burst pressure

- Materials: Pebax,Rilsan, Grilamid, Vestamid, Tecoflex, Pellthane, PET and more

Performance Specifications

- Tolerance down to +/-0.0005″

- Wall thickness down to 0.001″

- Concentricity greater than 90%

- Ovality within 1%