-

Custom Extrusion

Custom Extrusion

Our core competency is to manufacture the most challenging medical tubing in the industry. We process a wide range of high-performance materials to meet the most challenging applications

-

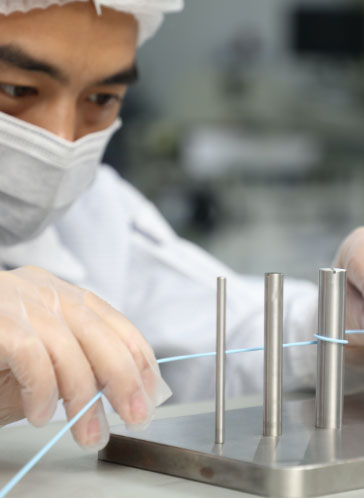

Secondary Operations

Secondary Operations

We provide a wide range of support services required for catheter manufacturing. These include tip forming, flaring, hole punching, machining, ultrasonic cleaning, bonding, and many more.

-

Assembly & Packaging

Assembly & Packaging

Take advantage of our low-cost option for assembly and packaging. We help customers exceed cost targets by utilizing our flexible workforce, machine automation, and streamlined operations.

-

Product Design & Development

Product Design & Development

Our expertise in polymer and material science is an excellent resource for our customers. We will collaborate closely with your engineering team, in order to optimize your product design’s manufacturability, durability and quality.

From material selection, to tooling design, all the way to rapid prototyping, AP Technologies is ready to assist you in bringing your product to market. -

Testing & Validations

Testing & Validations

We provide in-house testing services and can recommend solutions for quality test plans, test reports, and device protocols.

Our team is 100% focused in medical and our experienced QA team can assist you in meeting any regulatory and risk mitigation requirements backed by comprehensive and complete documentation. We offer our expertise with any FDA, CE, CFDA requirements you may have. -

Mass Production

Mass Production

We offer the best mass production value in the medical device industry.

AP Technologies has streamlined its manufacturing process to reduce cost, optimize efficiency, and deliver unparalleled value for your mass production needs. We utilize the latest technology in order to guarantee exceptional precision and repeatability.