What is Thin Wall Tubing?

16 March 21

Thin Wall Tubing

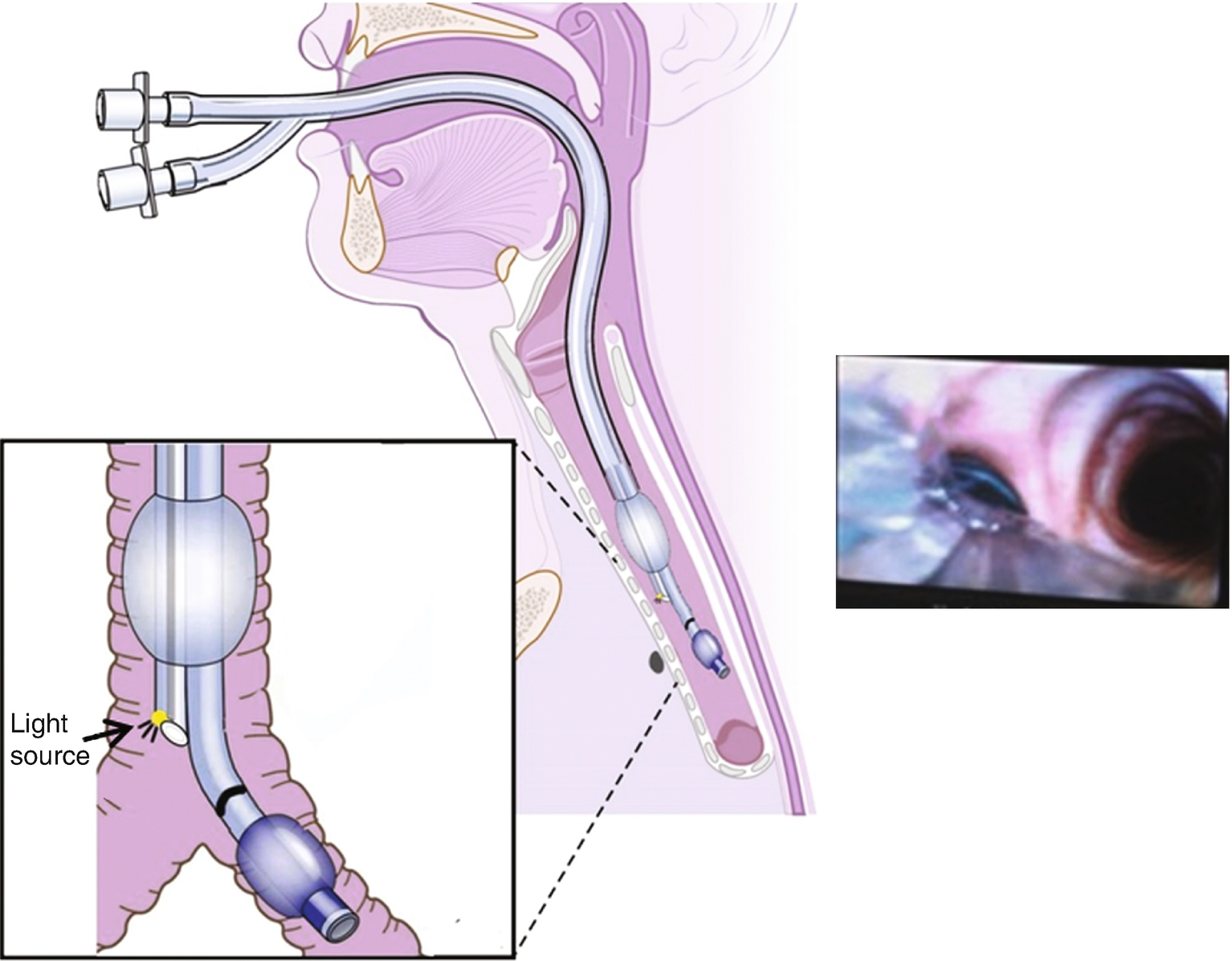

Many industries and businesses have incorporated the use of thin wall tubing. It has become quite successful due to its multi-functional properties. The use of thin wall tubing includes attention to detail when it comes to applications related to the medical field.

The reason thin wall tubing needs to the very precise in the medical field is because of the complexity of operations that need performance. They are a common part of equipment like catheters, lab instruments, and even in some surgery tools. Furthermore, they are also part of many diagnostic devices that help in detecting different diseases in different people.

As far as the other industries include, thin wall tubing plays a major role in many manufacturing procedures involved for different industries. They are a part of the chemical processing of different solvents. Moreover, they aid petroleum coating, pushing, color symmetry, and wiring treatment in the automobile industry. It is imperative that they are a part of many machines and petrol-related procedures.

Tube Fabrication information and leading Tube Fabrication Companies

The structure of thin wall tubing revolves around its thickness. Although the thickness does not impact the outside wall or the diameter the wall thickness can impact the inner diameter. Outside diameter is also known as OD and inner diameter also known as ID.

Usually, the inner diameter is the result of subtracting the outer diameter from the thickness of the wall. You can easily achieve a thin wall tubing structure by using steel, aluminum, copper, and brass materials. Sometimes using polymers or plastic that include PVC (polyvinyl chloride), Teflon, nylon, and (PET) polyethylene terephthalate are also a feasible choice.

There are many advantages that associate with the use of wall tubing that is thin. It is a great source for providing insulation. Moreover, it has great abilities to oppose chemical reactions and avoiding scuffs. It has a high resistance to high strains, the ability to endure high temperatures, and it prevents itself from any kind of mechanical damage.

With such durable qualities, they are perfect for imminent and up to the mark with the military standard. This is why they are a part of analogous procedures like attaching military vehicles. Often, thin-wall tubes are very flexible. Their flexibility allows its use in processes that allow movement. This specific feature allows it to be used in a vast variety of applications. Hence, they cater to multiple industries.

Manufacturing of Thin Wall Tubing

The manufacturing of thin wall tubing carries great significance. Usually, there are only two ways to process and manufacture a thin wall tube. Both are extremely efficient and require the following few steps. Those two processes are tube rolling and tube extrusion.

The Process of Tube Rolling

Categorically speaking, the process of tube rolling includes three major steps. The first step is to cut the already infused materials and roll them around in the mold. The second step usually involves the wrapping of the mold into a sleeve.

This step is very important in order to eradicate the chances of air that is retaining inside the mold sleeve. Here is where the heat acts as a curative. Lastly, the mold removes in order to release the desired hollow shape formulated during the whole process.

It is very important to roll the infused materials in a very tight wrapping to create a hollow mold of thin wall tubing. The whole idea is to amalgamate this procedure seamlessly in a tight bonding to produce the desired product.

There are many companies that perform tube rolling for producing thin-wall tubes. The use of tube rolling ensures that the thin-walled tubes are of great precision. This is an uncommon process, which is why it can get a bit expensive. Moreover, the factor of added precision gives it all the more reason to be more elaborate yet expensive.

The Process of Tube Extrusion

On the other hand, tube extrusion is a much more common and easier process when compared to tube rolling. During this process, the rounded objects get hit hard in order to introduce them inside a die. The die is already hollow and in a shape that is desirable by the manufacturer. The material introduced inside the die takes the shape of the die itself.

In this process, high temperature plays a very vital role. Without the use of high temperature, the material cannot insert inside the die; hence, the use of high temperature is very crucial. Furthermore, the material gets extrusion by using either of the two methods. Extruded material occurs after an indirect extrusion or a direct extrusion.

When direct extrusion takes place, the die remains constant at a place. Whereas, the material is hammered inside the opening of the hollow die. In indirect extrusion, the inside material extracts from the other opening of the die. The remaining material takes the shape of a hollow. This enables the formation of thin wall tubing which straightens by stretching it into a desirable shape and length. There are many stages in the fabrication of the tubing hence, there are many things that need consideration.

Benefits of Using Thin Wall Stainless Steel Tubes

There are many benefits associated with using thin wall Stainless steel tubes. The use of such tubes substantially decreases the cost of the whole project. The flexibility of such tubes, allows the machines to reduce the use of fittings and welded contraptions. This is why the production cost goes very low.

The whole procedure becomes crisp and much clean due to the reduced amount of welded points. It simultaneously reduces the occurrence of leakages too. The amount of chemical and liquid trapping in welded points reduces due to the flexible tube bending.

It is a great way to transport different kinds of liquid and gases. The already thin walls allow safe transportation. This is why steel is a great option when dealing with corrosive products and materials.

Although the thin wall stainless steel tube comes into existence after many stages, the use of precise CNC benders allows it to retain its own properties. This is very beneficial in performing further applications. The heat loss during the process is very less which is a great factor for industrial procedures. The tube bend is highly accurate that ranges from 0.005 inches to 0.010 inches.

They play a very important role in projects that require high-quality bending. Tubing inspections take place at regular intervals in order to avoid any inaccuracies in the outcome. It is a very practical way of saving money and time, plus it also eliminates a large quantity of manual work in making fixtures.

Summary

The use of thin wall tubing is becoming quite popular due to its diverse properties. Many companies provide their own stainless steel tubing charts for thin wall tubes. Usually, they match perfectly with the client’s requirements.

The bending properties of the tube allow it in many flexible applications in the industrial as well as the medical field. Its use in the medical field is helping surgeons to obtain very precise and accurate outcomes. It is very durable and long-lasting with many added benefits. It is the pinnacle of the advancement of technology in this world.

For More information, Contact Us Today!